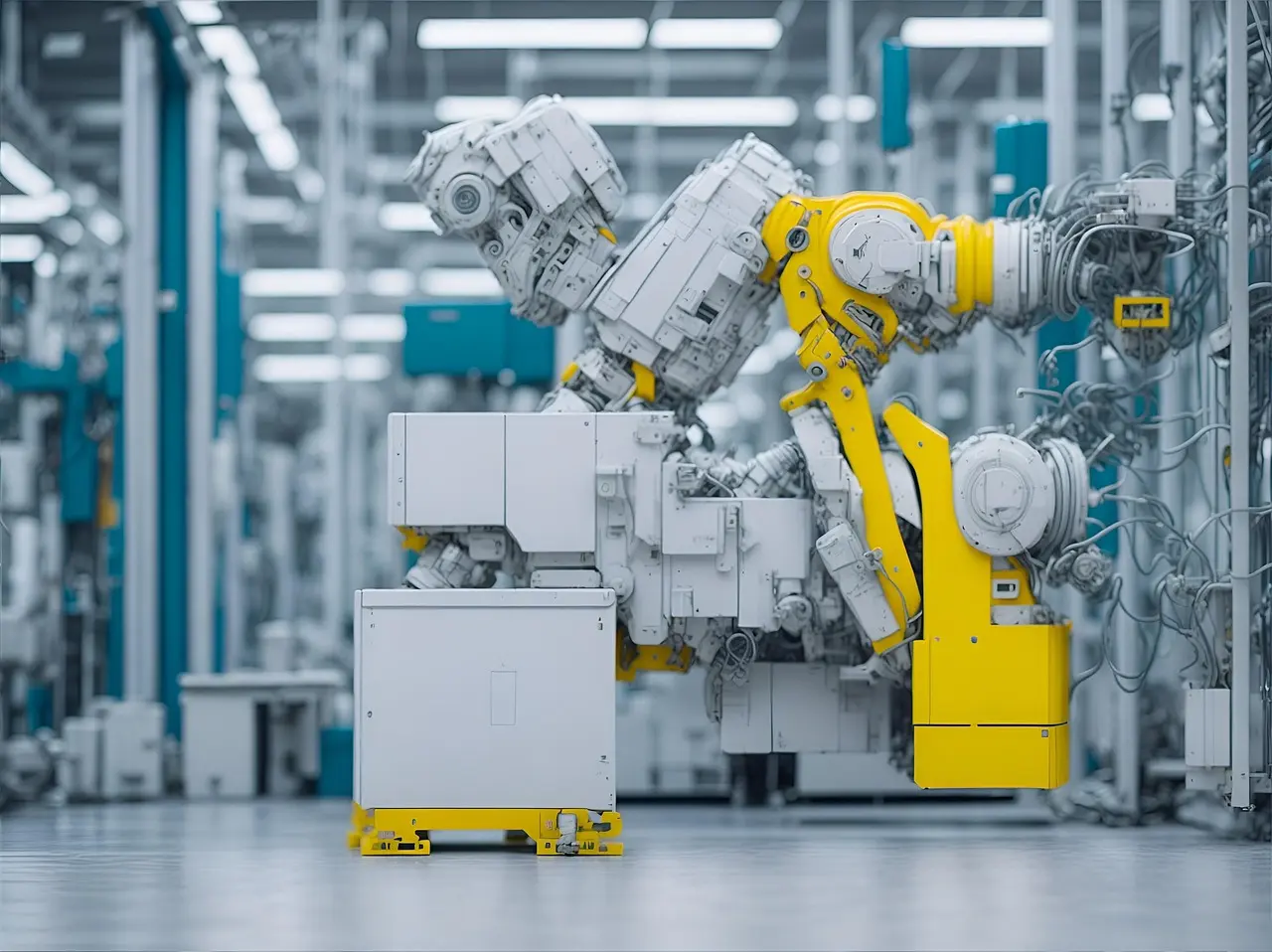

See operations with intelligent machine vision

Real-time safety detection, quality inspection, and AI-driven automation at scale

All Your Vision. One Platform.

OspreyX unifies computer vision, edge intelligence, and automation into a single platform — from real-time defect detection to continuous process optimization.

High-Precision Detection

Lower Rework & Waste

Continuous Insight

Deploy in Days, Not Months

Pre-trained AI models for common manufacturing scenarios mean you can go live in weeks — no PhD required, no experimental phase, just proven results from day one.

Pre-Trained Models

Fast Implementation

No PhD Required

Reduce Quality Costs Significantly

Automated inspection catches defects your team might miss, reduces rework, and eliminates manual quality checks — saving money while improving output consistency.

Automated Inspection

Reduce Rework

Lower Costs

Works With Your Existing Equipment

No need to rip and replace. OspreyX integrates with your current cameras, PLCs, and MES systems — protecting your existing investment while adding intelligent automation.

Easy Integration

No Equipment Change

Protect Investment

Industrial-Grade Vision Hardware

High-performance cameras and sensors designed for demanding manufacturing environments

Industrial Area Scan Camera

Industrial Robotic Arm

Industrial PTZ Camera

3D Vision Camera

Edge AI Camera

Industrial Inspection Drone

Vehicle Vision

Industrial Vision Sensor

Built for manufacturers,

by manufacturers

We understand your challenges because we've been there.

Empower every factory with intelligent vision

We believe AI-powered vision systems should be accessible to manufacturers of all sizes. Our mission is to deliver production-ready solutions that create real business value — not experimental R&D.

Teams around the world, serving you locally

With offices and partners across North America, Europe, and Asia, we provide local support with global expertise. Our distributed team ensures fast response times and deep understanding of regional requirements.

AI with purpose, vision with values

We are committed to responsible AI development, sustainable manufacturing practices, and ethical business operations. Our technology helps reduce waste, improve worker safety, and build a better future for manufacturing.