Precision That Sees. Intelligence That Acts.

Machine Vision Systems

Precision. Speed. Reliability.

End-to-end vision solutions—from sensors to 2D/3D systems and software—helping you boost quality, cut waste, and streamline automation.

What We Offer

If any of these sound like you—you’re exactly who we help.

Enterprise‑grade inspection pipelines

Automate visual QC on implants, devices, pills, vials, MRI/X‑ray scans.

AI‑enhanced anomaly detection

Solve inspection bottlenecks with custom deep‑learning models.

Plug‑and‑play modules

Cameras, lighting, 2D/3D analytics + SDKs—drop into your lines.

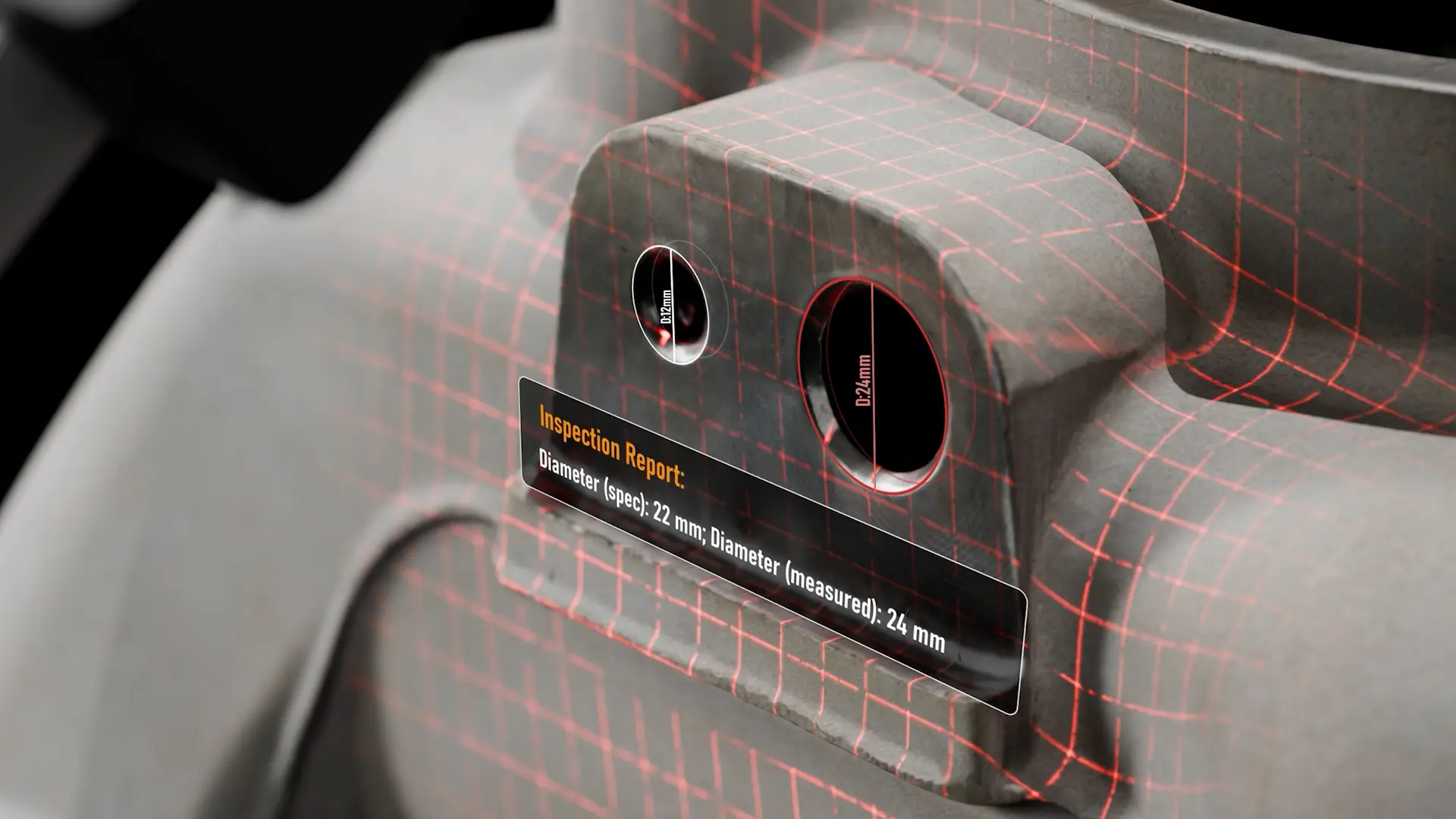

Configurable Core Inspection Capabilities

Tailored inspection features for diverse food and beverage applications

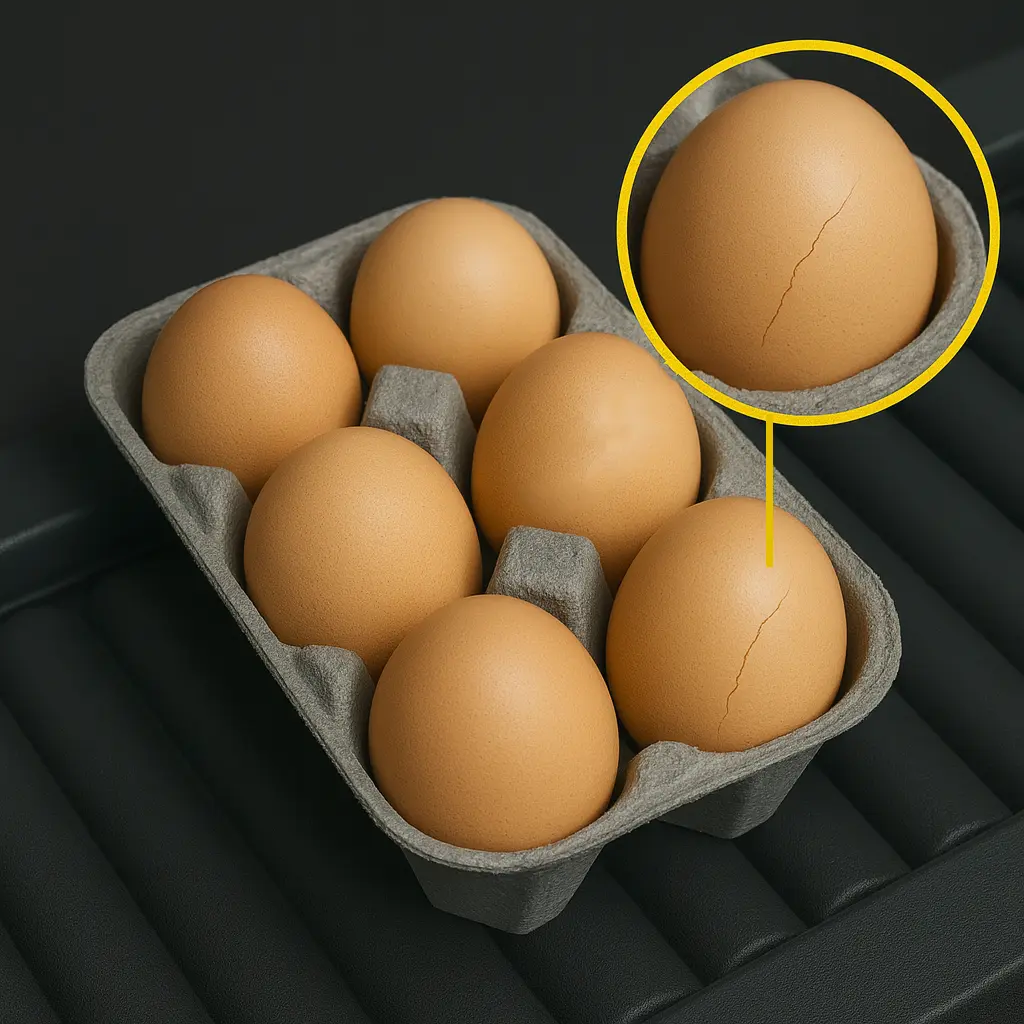

Egg Crack Detection

High-accuracy inspection to ensure quality and consistency

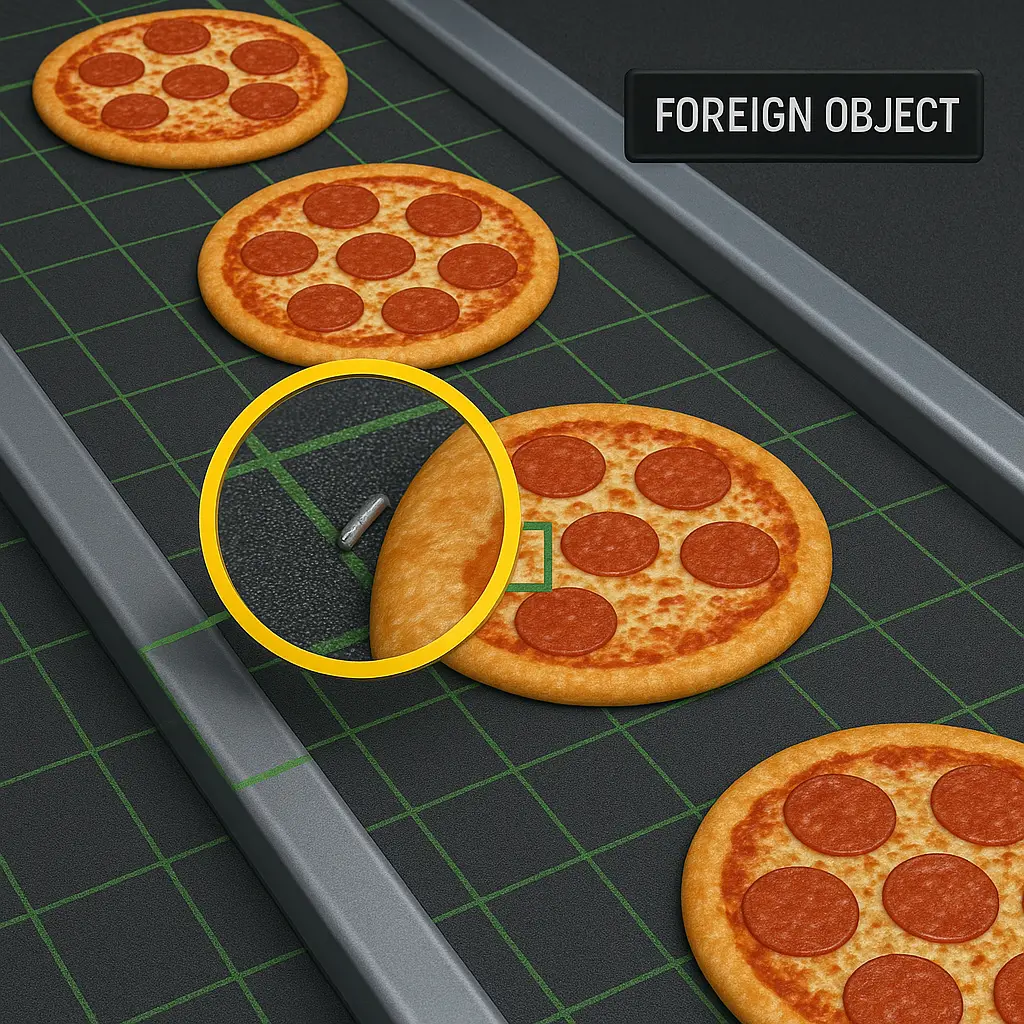

Foreign Object Capture

High-accuracy inspection to ensure quality and consistency

Snack Bar Check

High-accuracy inspection to ensure quality and consistency

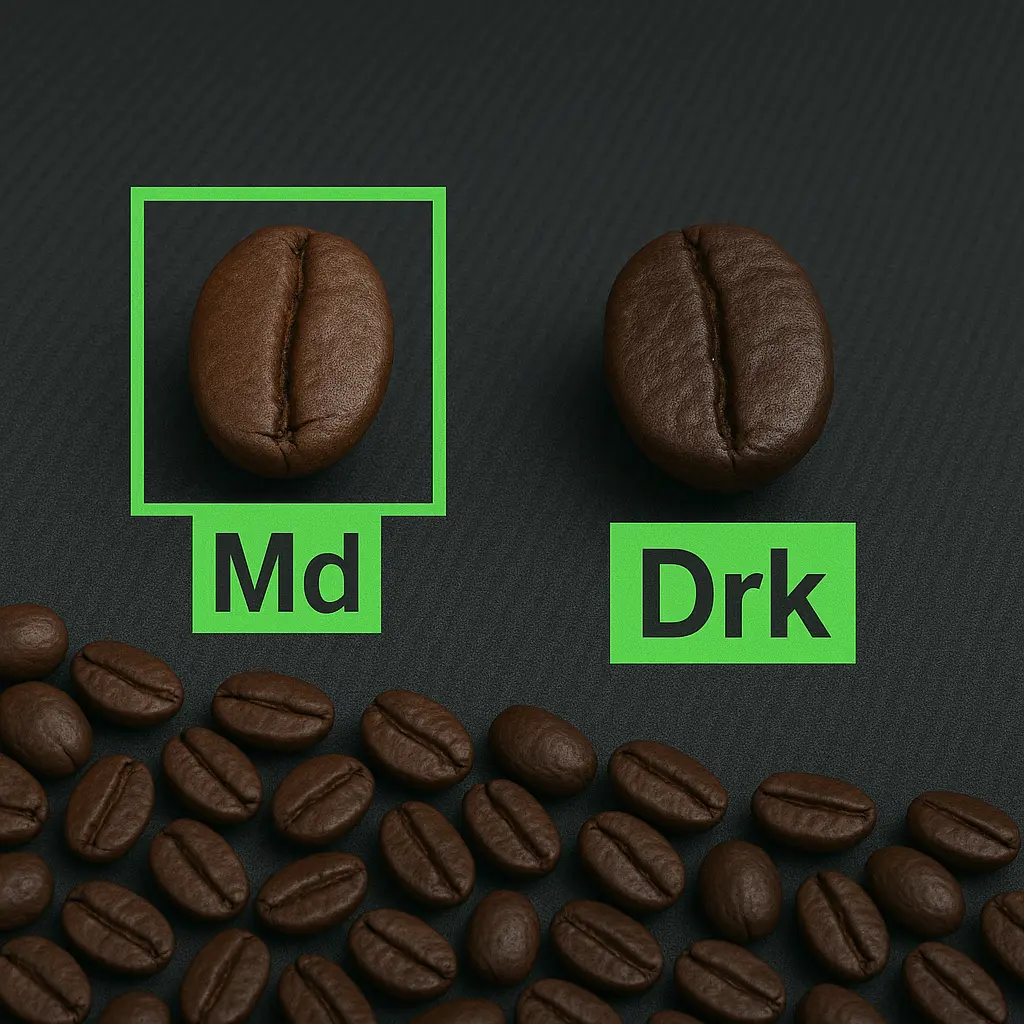

Coffee Bean Grading

High-accuracy inspection to ensure quality and consistency

Pizza Topping Check

High-accuracy inspection to ensure quality and consistency

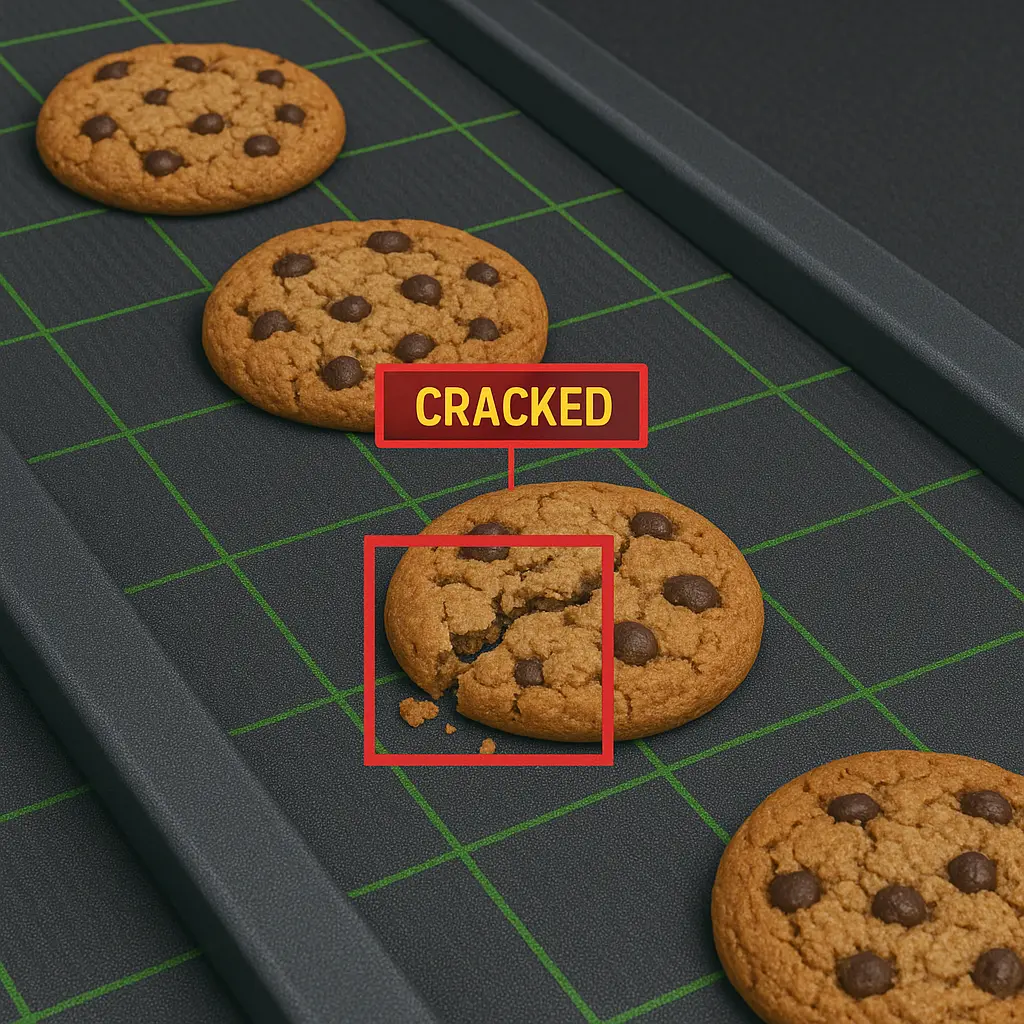

Cookie Crack Detection

High-accuracy inspection to ensure quality and consistency

Salmon Foreign Object

High-accuracy inspection to ensure quality and consistency

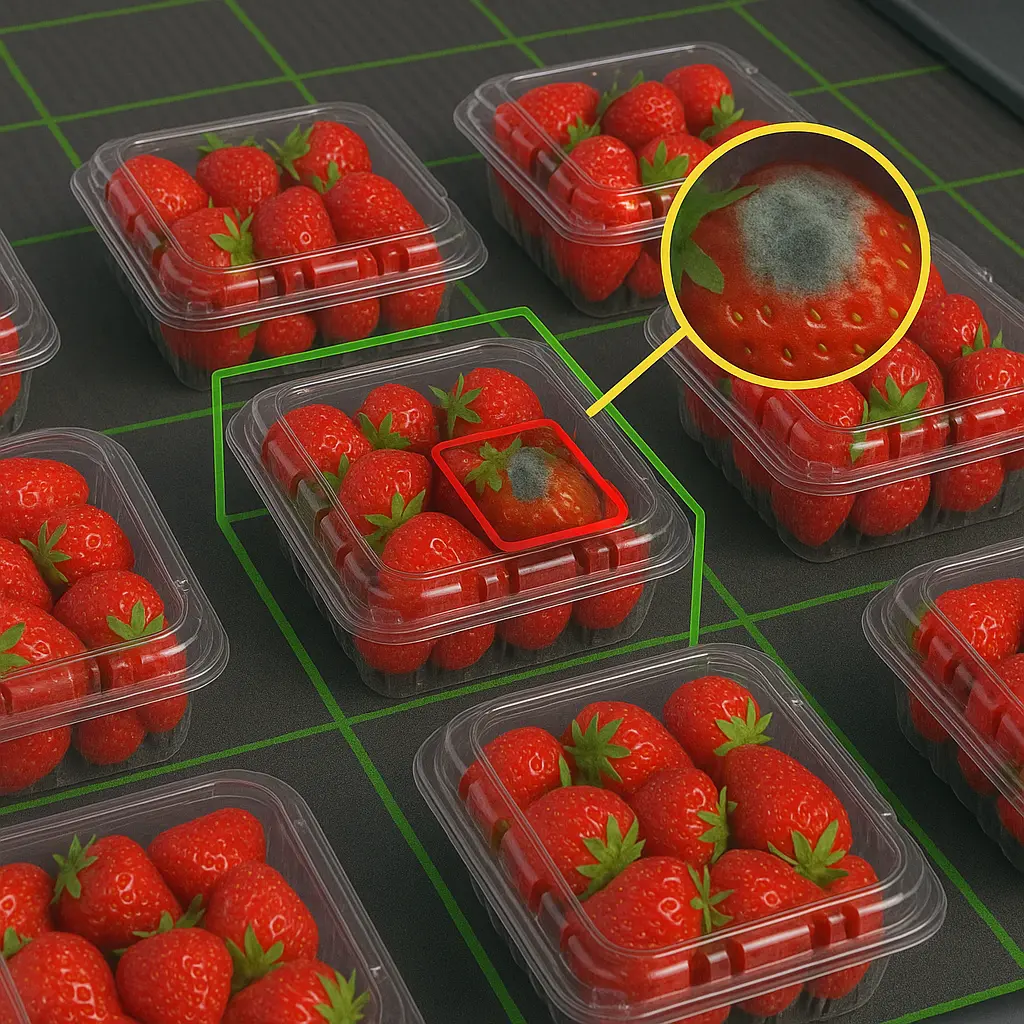

Strawberry Mold

High-accuracy inspection to ensure quality and consistency

What You're Dealing With vs. What We Deliver

See how OspreyX eliminates production pain points with smarter, real-world-ready machine vision.

Unreliable defect detection—systems miss defects intermittently in real-world production

Stable, consistent 99.9% defect catch rate, achieved through controlled lighting, calibration, and environmental tuning

Inconsistent lighting, shadows, reflections, and part variation cause false passes and fails

Professionally-engineered lighting designs with environment-adaptive controls ensure reproducibility

Manual or traditional vision setups require fixtures, limiting flexibility and driving up costs

Fixture-free, 360° inspection with unsupervised AI—no expensive mechanical jigs required

Long setup time, vendor delays, and expensive custom integrations

Modular plug-and-play solutions: cameras, optics, lighting, and AI models deployed in weeks

Integration nightmares—your MES/LIMS/PACS/databases don't sync with vision systems

Comprehensive support for API/SDK integration—seam, sync, secure.

Post‑implementation drift: no visibility into system health → undetected light degradation, miscalibration over time

Real-time diagnostics, alerting, and centralized monitoring ensure uptime and reliability—no silent failure

Regulations require traceable QC and audit logs, but manual work is time-consuming and error-prone

Auto-recorded reports, encryption, audit trails, compliance-ready from day one

AI vision engines often misclassify unusual cases, requiring intensive model tuning

Industry-trained base models fine-tuned to your data, with ongoing optimization support

99.9%

Proven accuracy on real production lines

Handles foil, matte, and glossy surfaces. No tuning or shielding. Reliable under motion and glare.

14 days

From boxed kit to working system

Lighting, lens, and logic pre-tuned. Field install completed in 2 weeks with zero code changes.

Full stack

Everything included, ready to scale

Kit includes camera, lighting, edge box, and software. Supports full-line rollout with no lock-in.

Smarter Vision Systems

for Manufacturing & MedTech

Precision that never fails

Real-world tested machine vision built for harsh conditions, ensuring accuracy in automotive, pharma, and food manufacturing.

Deploy fast. Pay fair.

Flat-rate pricing, transparent rollout, and no lock-in—just practical machine vision support designed for SMBs and enterprises.

Scale with confidence

Modular architecture allows you to expand from one line to global facilities without rebuilding your stack.