AI-Powered Bridge Inspection

Automate inspections, uncover defects, and ensure flawless quality with precision AI.

Complete Solutions

Built for Every Challenge

in Bridge Inspection

End-to-end inspection solutions to detect cracks, monitor structural integrity, and safeguard public safety.

90%+

Surface Coverage

Real-time

Defect Detection

Zero

Traffic Disruption

Inspection Applications

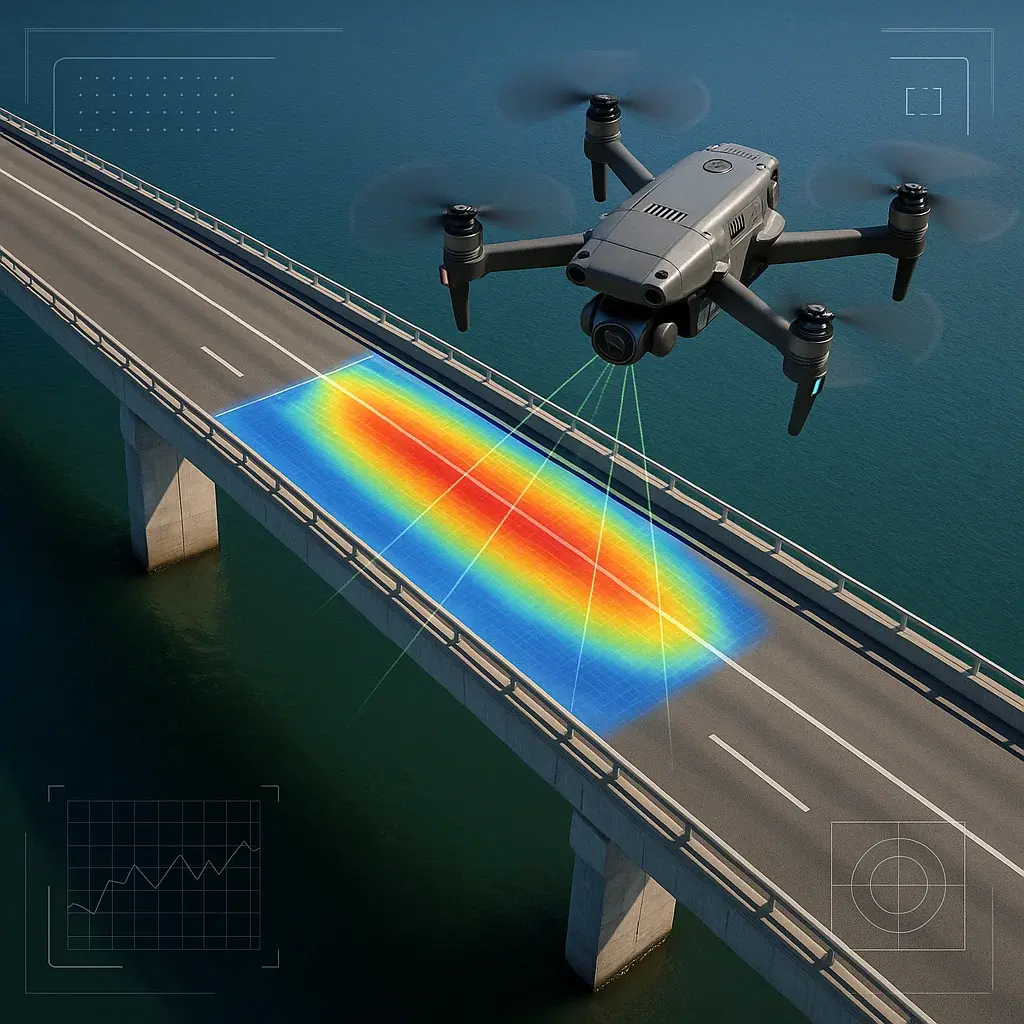

Comprehensive Bridge Assessment

Pillar Integrity Monitoring

Check column and pillar stability with precision scanning. Our AI-powered systems detect micro-cracks, surface degradation, and structural anomalies that could compromise bridge safety before they become critical issues.

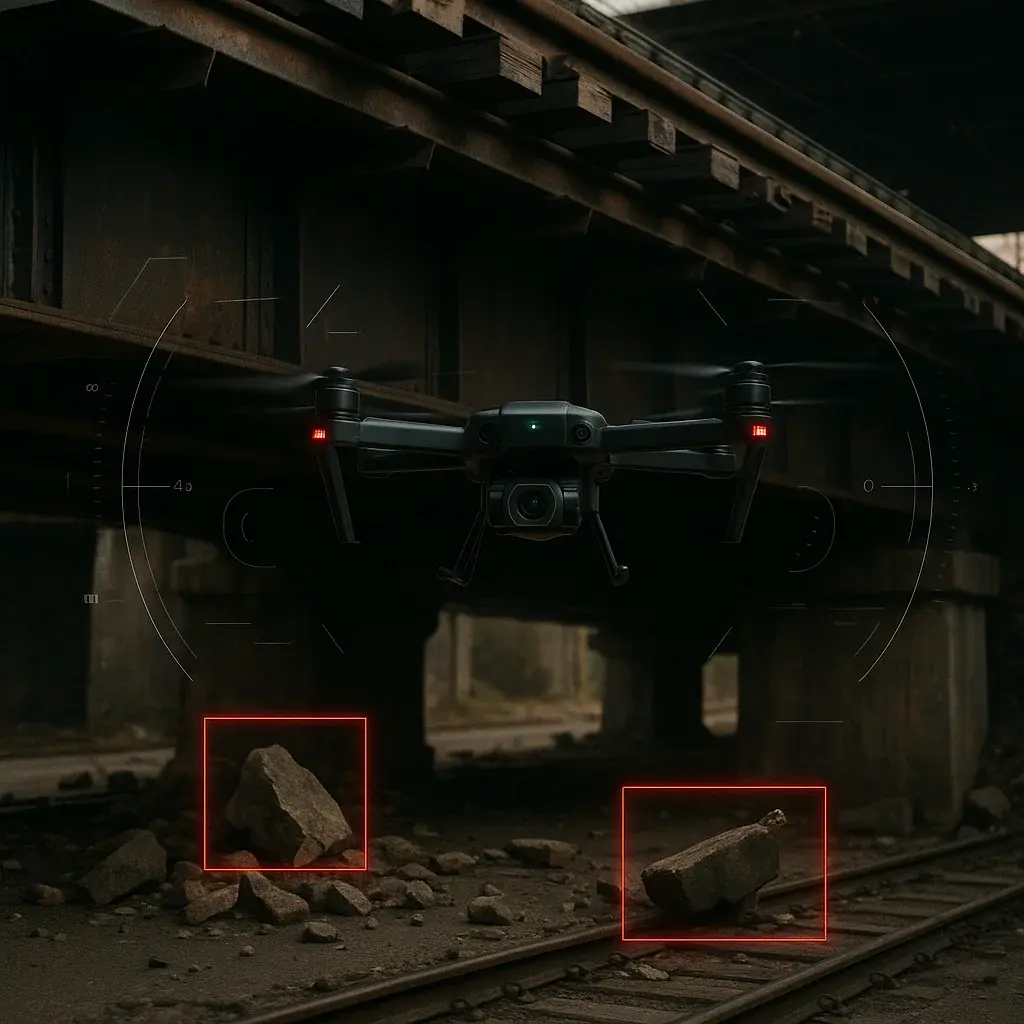

Underside Inspection

Drone scans hard-to-reach areas safely and efficiently. Access previously impossible inspection zones without scaffolding or traffic closures, capturing detailed imagery of bridge undersides and complex structural elements.

Cable & Joint Analysis

Inspect cables and joints for faults with millimeter precision. Identify corrosion, tension loss, and connection degradation across suspension cables, stay cables, and critical joint assemblies with automated defect detection.

AI-Powered Anomaly Detection

AI detects cracks and loose parts automatically. Advanced computer vision identifies structural defects, material degradation, and potential failure points that human inspectors might miss, ensuring comprehensive safety assessment.

Why Most Vision Systems Fail in Bridge Inspections

If any of these sound like you—you’re exactly who we help.

GPS drops out under bridges.

Most drones can’t fly stably without GPS. OspreyX vision+LiDAR holds steady under complex structures.

Wind gusts = shaky data.

Traditional cameras blur in tough environments. OspreyX delivers clear, stable scans in high winds.

Critical spots get missed.

Scaffolding and manual checks only cover part of the bridge. Our drones capture 90%+ of surfaces.

New structures break old models.

Legacy AI retrains endlessly. OspreyX adapts instantly to new environments without downtime.

Data takes weeks to process.

Raw LiDAR is massive. Our pipeline auto-merges point clouds—results in hours, not weeks.

ROI is hard to prove.

Owners demand proof first. OspreyX demonstrates value in a single day—no closures required.