Precision That Sees. Intelligence That Acts.

AI Vision for Food & Beverage manufacturing

Reduce Recalls by 70% | Cut QA Costs by $200K/Year

Smarter Vision. Safer Products.

AI-powered inspection that detects defects in real time, reduces waste, and keeps production moving without interruption.

What You’re Dealing With vs What We Deliver

A side-by-side view of real manufacturing challenges vs. the measurable outcomes our AI vision system delivers in production environments.

Pain Points

$200K+/year lost on manual QA labor

Audit preparation consumes 2–3 weeks per cycle

$10K/hour cost of unplanned downtime

Average product recall = $5M+ loss & brand damage

Our Solutions

Automated inspections catch >95% of defects before shipment

Audit-ready reports generated instantly (FDA/USDA compliant)

Real-time edge alerts reduce downtime incidents by 40%

360° vision coverage across multiple product lines

Inspection Modules That Stop Defects Before They Ship

Customizable AI vision features for critical food & beverage QA

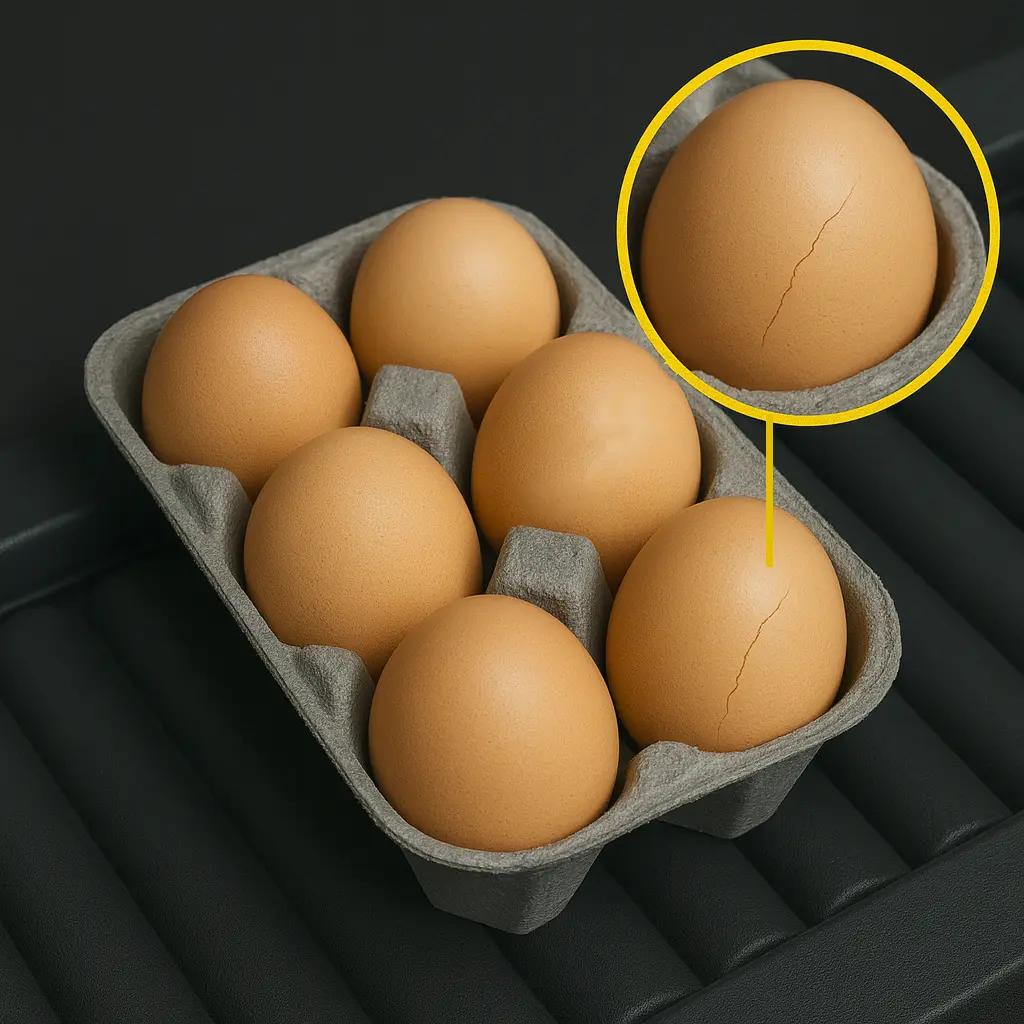

Egg Crack Detection

Catch micro-cracks before cartons leave the line — reduce returns & recalls.

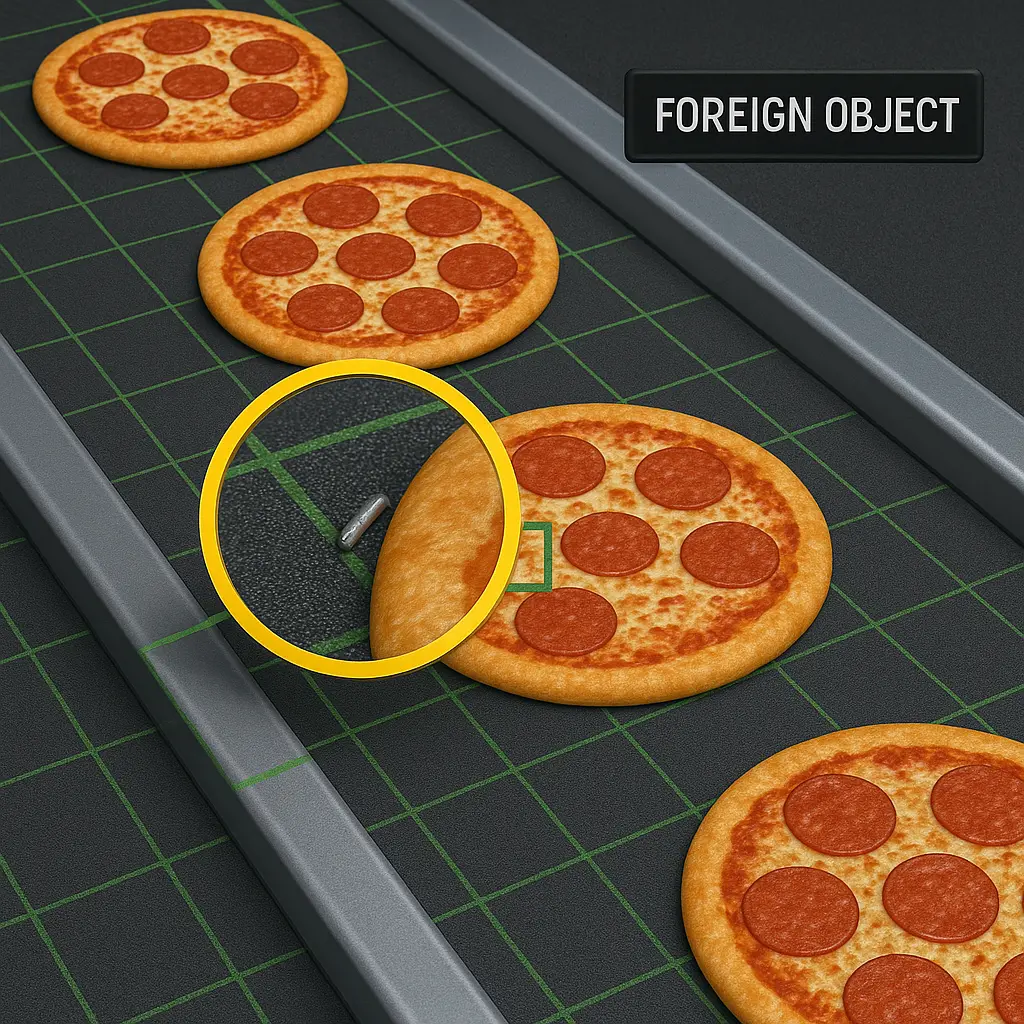

Foreign Object Capture

Instantly flag plastic, metal, or glass contamination to stay FDA compliant.

Snack Bar Check

Verify shape, size, and topping consistency for perfect retail presentation.

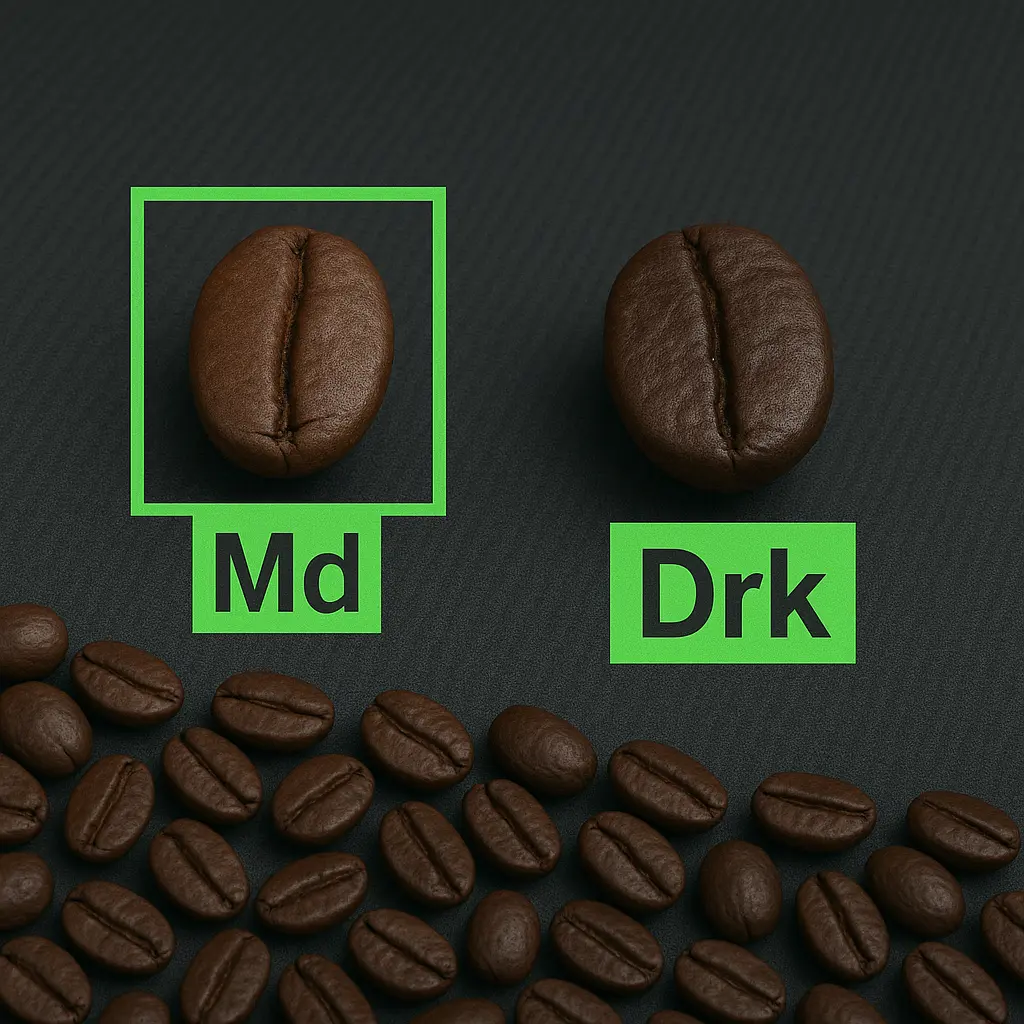

Coffee Bean Grading

Grade beans by color & roast to guarantee uniform flavor profiles.

Pizza Topping Check

Confirm topping placement & portioning to cut waste and rework.

Cookie Crack Detection

Spot cracks & breakage early to avoid customer complaints.

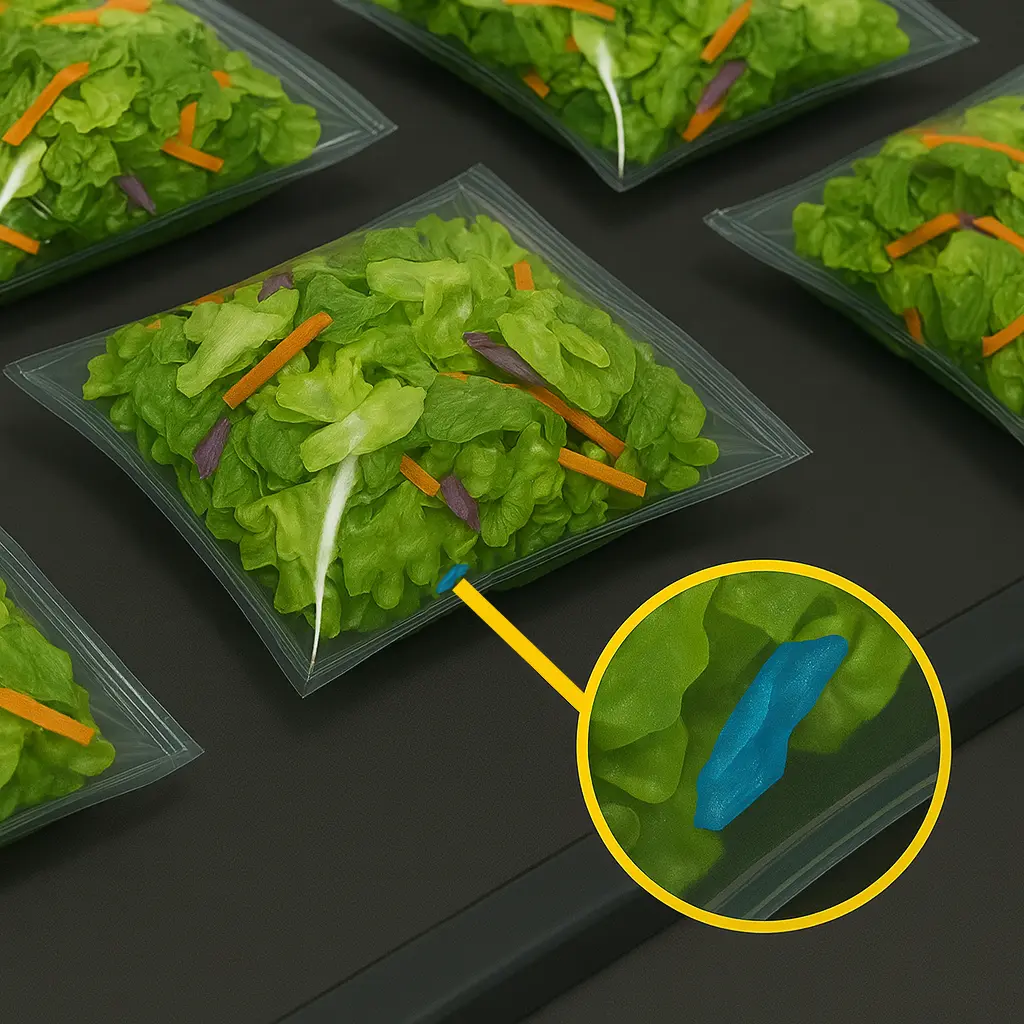

Salmon Foreign Object

Detect hidden contaminants in high-value protein products.

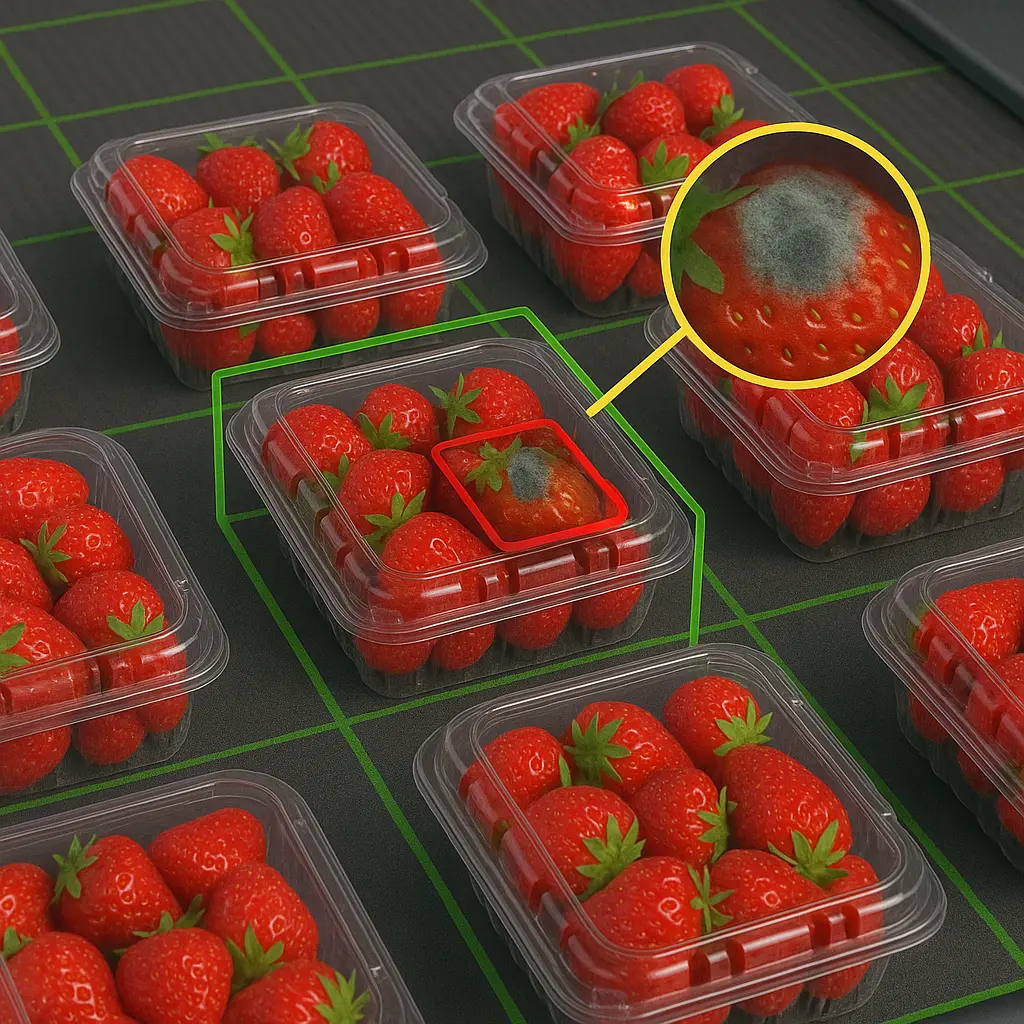

Strawberry Mold

Catch early mold growth before it spreads across batches.

Typical Audience Personas

Owner / CEO

Key Concerns

Decision Logic

“If this system can prevent million-dollar recalls and save $200K in QA costs each year, it’s a no-brainer investment.”

Operations Director

Key Concerns

Decision Logic

“Needs a proven Edge AI solution that keeps lines running 24/7 and minimizes costly downtime.”

QA Manager

Key Concerns

Decision Logic

“Wants automated, audit-ready reports and high-accuracy defect detection to cut inspection time and paperwork by 50%.”

EHS Manager (Safety & Compliance)

Key Concerns

Decision Logic

“Looking for AI systems that prevent accidents, reduce OSHA risks, and prove compliance during safety audits.”

AI That Makes Every Batch Perfect

From robotic handling to flavor consistency — our ready-made AI workflows help food & beverage manufacturers cut waste, boost efficiency, and deliver consistent quality at scale.

Production Efficiency

Automated robotic pick & place

Conveyor line monitoring

Bottle & can fill-level inspection

Quality & Freshness

Beverage clarity & color analysis

Ripeness & freshness detection

Dough & batter consistency monitoring

Consistency & Experience

Cap & seal integrity inspection

Foam & carbonation analysis

Cooked food doneness inspection

Smarter Vision for Smarter Manufacturing.

Juice Filling Line

Cookie Production Line

Bottled Water Conveyor

Berry Sorting

Biscuit Forming Line

Canned Beverage Line

Tomato Sorting

Juice Bottling Line

Meat Patty Production

Glass Bottle Filling

Juice Filling Line

Cookie Production Line

Bottled Water Conveyor

Berry Sorting

Biscuit Forming Line

Canned Beverage Line

Tomato Sorting

Juice Bottling Line

Meat Patty Production

Glass Bottle Filling