Precision That Sees. Intelligence That Acts. Packaging & Logistics Vision

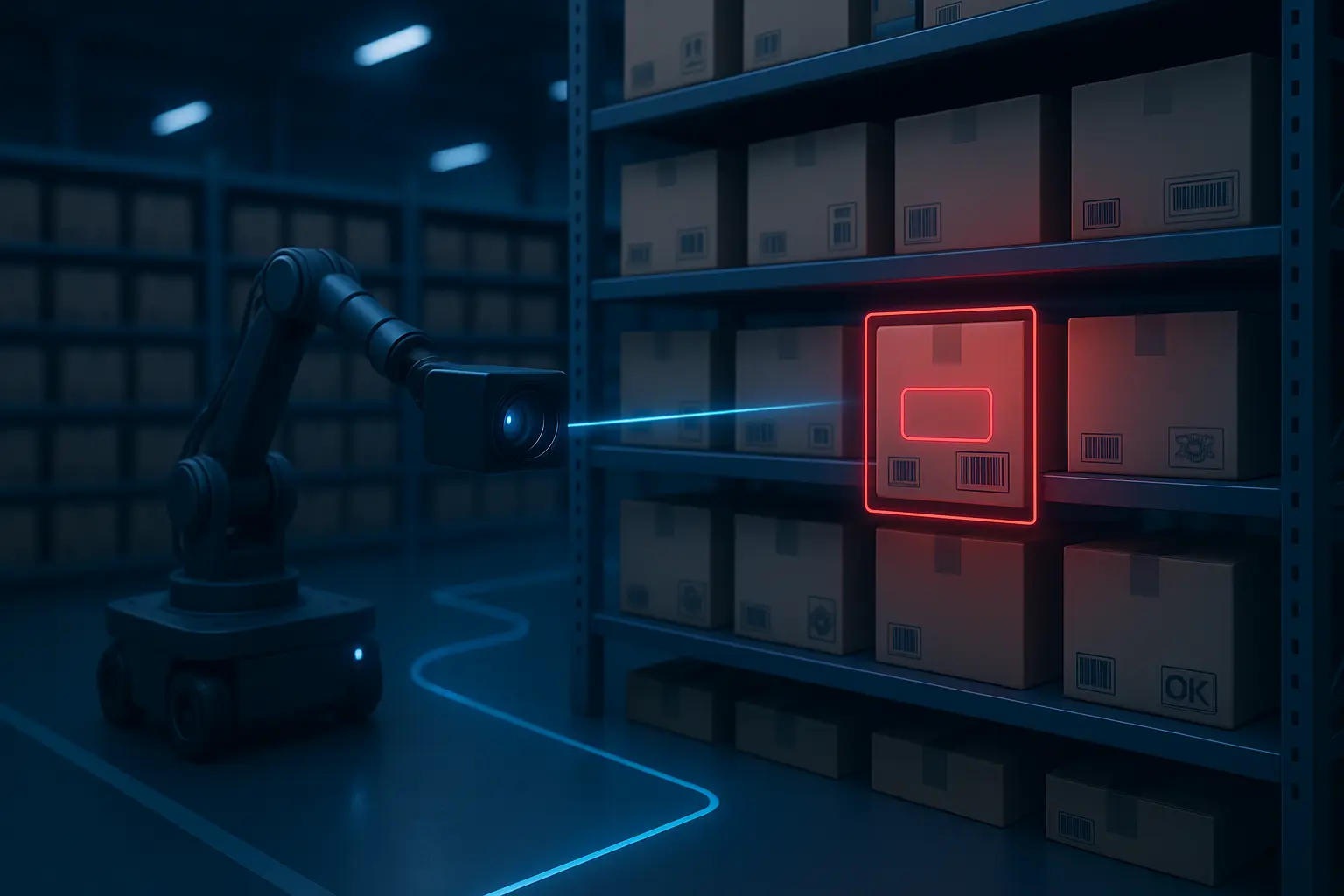

Machine vision built for real-world challenges in logistics, warehousing, and packaging. OspreyX adapts to your operation—so you never lose time, accuracy, or efficiency.

Industrial Vision

Built for Modern

Logistics

AI-powered vision systems that ensure consistent scanning, verification, and classification—at operational scale.

Designed for real-world warehouse environments—reducing errors, improving traceability, and keeping operations moving smoothly.

Proven accuracy

in production environments

Scales with

growing volumes

Seamless WMS

& automation integration

Core Applications

Precision Vision for Every Stage

Precise Label Detection

High-speed barcode and label reading for 1D, 2D, and QR codes. Auto-check for misaligned, missing, or damaged labels with 99.9% accuracy. Integrates seamlessly with printers, diverters, and WMS/ERP systems for real-time tracking and traceability.

Instant Defect Capture

Automated package inspection detecting dents, tears, contamination, and seal failures in real-time. Works under variable lighting and motion conditions, processing over 10,000 items per hour with consistent accuracy across different packaging materials and formats.

Smart Inspection for Variable Products

Volume and shape classification for automated sorting. Configurable for SKU, carrier, or zone-based routing with real-time location tagging. Adapts to new product variations without downtime or extensive retraining, maintaining throughput and accuracy.

Why Most Vision Systems Fail in Packaging & Logistics

If any of these sound like you—you’re exactly who we help.

Lenses fog up. Everything goes blurry.”

Humidity ruins most cameras. We use sealed, glare-proof lenses designed for food-safe environments.

Fast lines = motion blur = missed defects.

Our 500+ ppm AI vision tracks every item without smearing or skipping.

New packaging? Model breaks—again.

Stop retraining. OspreyX adapts to packaging changes without downtime.

It flags everything. Even what’s not broken.

We detect true defects, not harmless variation—so your line stays moving.

We keep adjusting settings every week.

OspreyX self-calibrates and alerts you only when needed. Hands-off, stress-free.

Support takes days. Production can’t wait.

Our U.S.-based team responds in under 24 hours. Real help, real fast.