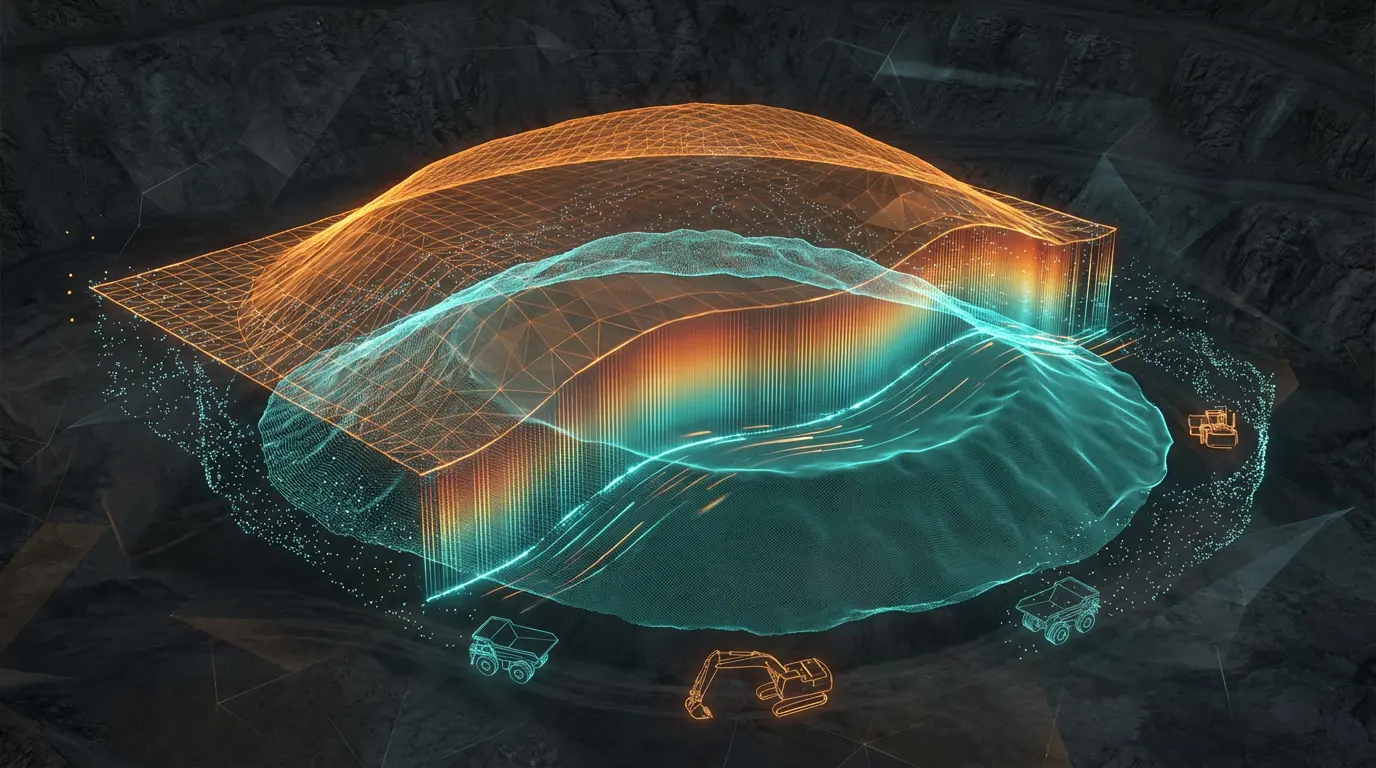

Daily Production-Ready 3D Data Used in Mining Operations

Based on drone 3D modeling and measurement, continuously delivering inventory, progress, and change metrics used directly for daily mining production decisions.

Why OspreyX

We Deliver Data, Not Models

Continuous, comparable production data — inventory, progress, and change — built over time, not from a single flight.

Jan 2024

Mar 2024

May 2024

Jul 2024

Sep 2024

Dec 2024

Initial Survey

Three Production Results

Inventory

Stockpile Volume

Current stockpile volume and net change since last measurement.

Progress

Excavation Progress

Actual excavation compared to plan. Over- or under-excavation clearly identified.

Change

Terrain Change

Surface changes tracked over time. Each flight adds to a continuous record.

Core Applications

Daily Operations This System Supports

Stockpile Management

High-frequency stockpile measurement with consistent results. Current volume and net change are automatically calculated and used for daily production tracking.

Production Progress Tracking

Actual excavation compared to plan on a weekly or monthly basis. Over- or under-excavation is clearly identified, with progress tracked over time.

Site Change Tracking

Site conditions understood without being on-site. Key area changes are available on demand, with terrain changes tracked as a continuous record.

Team Coordination

Survey, production, and management teams work from the same map. All decisions are based on a single source of production data.

Safety & Security Monitoring

Real-time AI-powered surveillance monitoring personnel safety compliance, detecting unauthorized access, and identifying potential hazards across mining operations 24/7.

Advanced Features

Why Mining Operations Choose OspreyX

Because it works in mining conditions, not just on paper. Because you get help when you need it, not a week later. Because it doesn't require replacing everything you already have.

Measurement Frequency

Traditional: Infrequent measurement cycles. New: High-frequency, repeatable measurements delivering daily production data.

Data Timeliness

Traditional: Data arrives after operations. New: Inventory, progress, and change data available on demand.

Data Consistency

Traditional: Multiple datasets in parallel. New: A single source of truth shared across survey, production, and management.

Decision Basis

Traditional: Decisions driven by experience. New: Decisions driven by measured change used directly in production.

Included with every deployment

Proven AI Vision Solutions for Mining & Quarries

See How OspreyX Can Transform Your Operation

Join leading mining companies using AI vision to reduce incidents, prevent downtime, and optimize material handling. Schedule a demo to see our platform in action at a site like yours.

High Accuracy from Day One

Solution Design

Transparent Pricing & Specs

Live Demo